Textile

Mechanical Seals for Textile Industry

Textile

Mechanical seals for Textile Industry

Mechanical seals play a critical role in various equipment and processes involved in the manufacturing of textiles

In the textile industry, mechanical seals play a critical role in various equipment and processes involved in the manufacturing of textiles. Here are some key applications of mechanical seals in the textile sector:

- Pumps: Textile manufacturing processes often require the circulation and transfer of various liquids such as water, dyes, chemicals, and finishing agents. Mechanical seals in pumps help prevent leakage of these fluids, ensuring efficient operation and preventing contamination of the product.

- Dyeing Machines: Dyeing is a crucial process in textile manufacturing, where fabric is colored to achieve the desired appearance. Dyeing machines use mechanical seals to prevent leakage of dye liquor and maintain a sealed environment during the dyeing process, ensuring uniform color distribution and preventing product defects.

- Finishing Equipment: Finishing processes such as coating, laminating, and impregnating are used to enhance the properties of textiles, such as water repellency, flame resistance, or wrinkle resistance. Mechanical seals in finishing equipment help prevent leakage of finishing chemicals and ensure uniform application on the fabric surface.

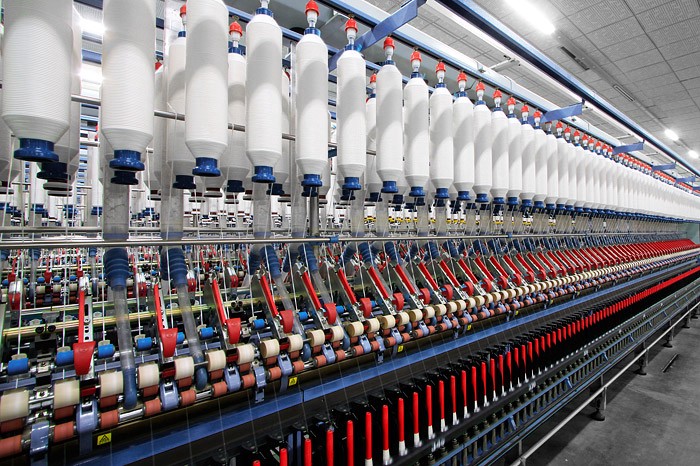

- Extruders and Mixers: Extruders and mixers are used in the textile industry for compounding polymers, producing fibers, and blending additives. Mechanical seals in extruders and mixers help prevent leakage of molten polymers, additives, or solvents, ensuring safety and preventing product contamination.

- Heat Setting Machines: Heat setting is a process used to stabilize the dimensions of synthetic fibers and improve their mechanical properties. Mechanical seals in heat setting machines help prevent leakage of hot air or steam, ensuring uniform heat distribution and preventing energy loss.

- Printing Equipment: Textile printing involves applying patterns or designs onto fabric using various printing techniques such as screen printing, rotary printing, or digital printing. Mechanical seals in printing equipment help prevent leakage of printing inks, dyes, or chemicals, ensuring accurate and consistent printing results.

- Calenders and Presses: Calenders and presses are used in textile manufacturing to improve the surface finish, thickness, and smoothness of fabrics. Mechanical seals in calenders and presses help prevent leakage of heat transfer fluids or hydraulic oils, ensuring uniform pressure distribution and preventing equipment damage.

- Washing and Drying Equipment: Washing and drying processes are essential for removing impurities, residues, and excess chemicals from textiles. Mechanical seals in washing and drying equipment help prevent leakage of water, steam, or drying gases, ensuring efficient operation and preventing energy loss.

In the textile industry, mechanical seals must be designed to withstand the specific operating conditions, including temperature, pressure, and chemical compatibility. Regular maintenance and inspection of mechanical seals are essential to ensure their reliable performance and prevent costly downtime. Additionally, the selection of appropriate materials and seal configurations is crucial to optimize seal performance and longevity in textile manufacturing applications.

Today’s dye & finishers are faced with the challenge of keeping multiple manufacturers of various older equipment in operational order. Lifter reels, dye pumps, and sample pumps are just some of the equipments. At Sealomech Engineering we continue and thrive to analyze the most challenging problems and respond with a high-tech product line that meets our customers’ demands for seal solutions.

Email us: info@sealomech.com or Call us: +91-8898230000