Requirements for service and repairing of Canned motor pumps in India

Requirements for service and repairing of Canned motor pumps in India

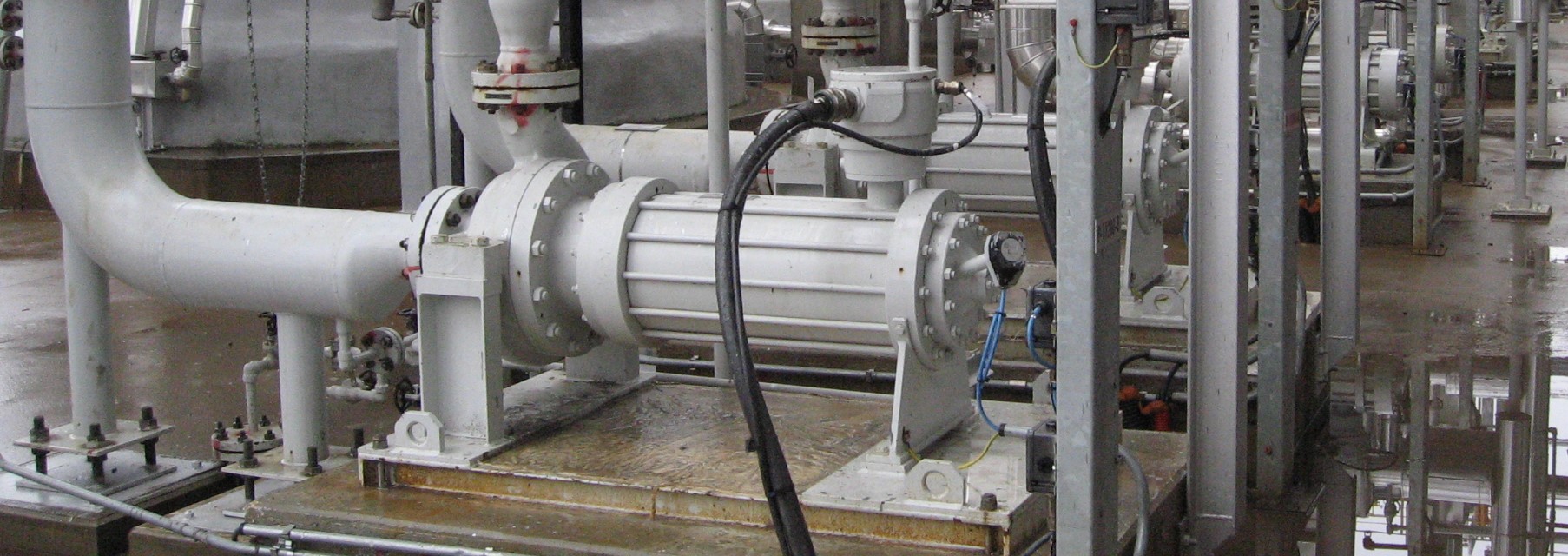

Canned motor pumps require careful attention to detail and adherence to proper procedures to ensure optimal performance and safety

Servicing and repairing canned motor pumps require careful attention to detail and adherence to proper procedures to ensure optimal performance and safety. Here's a general guide on how to approach the service and repair of canned motor pumps:

- Safety First: Before beginning any work, ensure that the pump is completely shut down and isolated from its power source. Follow all safety protocols and wear appropriate personal protective equipment (PPE) such as gloves and safety glasses.

- Inspection: Start by visually inspecting the pump for any obvious signs of damage or wear. Look for leaks, corrosion, or unusual noises. Check the electrical connections for any signs of damage.

- Cleaning: Clean the exterior of the pump to remove any dirt, debris, or contaminants that may interfere with its operation. Use a mild detergent and water solution for cleaning.

- Disassembly: If servicing requires disassembly, refer to the manufacturer's instructions for proper procedures. Take note of the orientation and placement of components as you disassemble the pump to aid in reassembly.

- Component Inspection: Inspect all internal components for wear, damage, or signs of deterioration. This includes impellers, bearings, seals, and motor windings. Replace any components that show signs of excessive wear or damage.

- Replacement Parts: Use only genuine replacement parts recommended by the manufacturer to ensure compatibility and optimal performance.

- Seal Inspection and Replacement: Pay particular attention to the seals in canned motor pumps, as they are critical for preventing leaks and maintaining proper operation. Inspect seals for signs of wear or damage and replace them if necessary.

- Motor Inspection: Check the motor windings for signs of overheating or damage. Test the motor's electrical connections and insulation resistance to ensure proper functioning.

- Reassembly: Carefully reassemble the pump, following the manufacturer's instructions and ensuring that all components are properly aligned and secured.

- Testing: After reassembly, test the pump to ensure that it operates correctly. Check for leaks, abnormal noises, and proper flow rates. Verify that the motor is functioning within its specified parameters.

- Maintenance Schedule: Establish a regular maintenance schedule for the canned motor pump, including routine inspections, cleaning, and lubrication as recommended by the manufacturer.

- Documentation: Keep detailed records of all maintenance and repair activities performed on the pump, including dates, parts replaced, and any observations or findings.

By following these steps and adhering to proper maintenance practices, you can ensure the reliable operation and longevity of canned motor pumps. If you're unsure about any aspect of servicing or repairing the pump, it's always best to consult with a qualified technician or contact the manufacturer for guidance.

Email us: info@sealomech.com or Call us: +91-8898230000