History of Mechanical Seals for pumps

Purpose, History and Development of Mechanical Seals for pumps

Invented in late 1930’s early 1940’s as more equipment

- moved from steam-powered reciprocating motion to

- electric powered rotary motion

- More efficient sealing alternative to soft packing

- Mechanical Seals and soft packing create a seal between

- a rotating drive shaft and the static casing wall. This

- Retains media inside the equipment

- Prevents media entering electrical parts of the equipment

- Allows the power source to be external to the hydraulic parts

Originally mechanical seals were developed to overcome the negative issues affiliated with packed stuffing boxes. Simple mechanical seals offered an alternative to fluid leakage; none, least not detectable with the naked eye.

They eliminated the need for a routine maintenance schedule as once properly selected and installed they would function without attention until the seal faces themselves wore out which could be years later, versus packing months.

While initial cost to purchase a pump with a simple seal may have been higher their were no post installation costs and the return for this investment could be realized immediately with virtually zero product loss over the life of the seal. Mechanical seals can handle much higher temperatures and pressures than ever before and can meet zero tolerance fugitive emission standards.

Sealing The Liquid

- Early packing styles did not seal very well. In fact, until recently, braided packing styles required varying amounts of leakage for lubrication. If leakage was not permitted to occur, the packing would literally “burn up” and often cause severe damage to the pump shaft. Even with adequate leakage for lubrication, pump shaft wear was a commonly expected occurrence and as the shaft wore it would in turn, cause poor shaft packing life.

- As leakage becomes more excessive, the gland is tightened to reduce leakage.

- With the introduction of mechanical seals, this leakage could be controlled to a much greater degree.

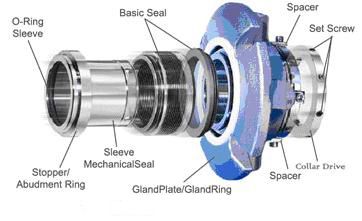

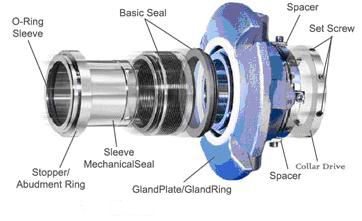

- Let’s look at the same pump with a mechanical seal installed. Note that the seal shown is an Series - 1000 with O-Ring type stationary and a set screw collar.

- You have probably taken notice of the illustration showing minor leakage to atmosphere. It is appropriate to point out at this time

Purpose of mechanical seals, history of mechanical seals, developments of mechanical seals, mechanical seals and pumps