Different types of rotary joints and their industrial applications

Different types of rotary joints and their industrial applications

The introduction and classification of rotary joints, how to install and maintain rotary joints, how to work with rotary joints, etc. in industrial applications

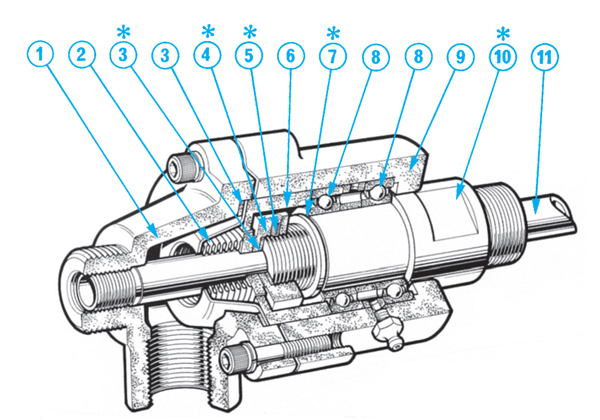

Rotary joints, also known as rotary couplings or swivels, are devices that allow the transfer of fluid, gases, or electrical signals between rotating and stationary parts of a system. They find applications in various industries and systems where continuous rotation is required. There are different types of rotary joints designed for specific purposes. Here are some common types and their applications:

- Fluid Rotary Joints:

- Hydraulic Rotary Joints: Used in hydraulic systems to transfer hydraulic fluid between rotating and stationary parts, commonly found in heavy machinery and industrial equipment.

- Pneumatic Rotary Joints: Similar to hydraulic rotary joints but designed for the transfer of compressed air or gases, commonly used in pneumatic tools and automation systems.

- Electrical Rotary Joints:

- Slip Rings: Used to transfer electrical power or signals across rotating and stationary parts. Common applications include rotating cameras, radar systems, and wind turbines.

- Combination Rotary Joints:

- Hydraulic-Pneumatic Rotary Joints: Combines the capabilities of both hydraulic and pneumatic rotary joints, suitable for systems requiring the transfer of both fluids.

- Fluid-Electrical Rotary Joints: Integrates fluid and electrical connections in a single rotary joint, useful in applications such as robotics and automation.

- Multi-Passage Rotary Joints:

- Multi-Channel Rotary Joints: Have multiple channels for the simultaneous transfer of different fluids or signals. These are often used in complex industrial machinery where multiple functions need to be performed simultaneously.

- High-Speed Rotary Joints:

- High-Speed Air Bearings: Used in high-speed applications where low friction and minimal wear are critical, such as high-speed spindles in machining centers.

- Fiber Optic Rotary Joints:

- Fiber Optic Rotary Joints: Transmit optical signals across rotating and stationary parts. They are commonly used in applications like military surveillance systems and medical imaging devices.

- Welding Rotary Joints:

- Welding Rotary Joints: Designed specifically for welding applications, allowing the transfer of gas and/or water for cooling through the welding torch.

- Automotive Rotary Joints: Used in automotive applications for transferring fluids like brake fluid or coolant between rotating and stationary parts.

- Medical Rotary Joints:

- Medical Rotary Joints: Applied in medical equipment, such as rotating joints in imaging devices or robotic surgical systems.

- Food and Beverage Rotary Joints:

- Sanitary Rotary Joints: Designed for food and beverage processing equipment, ensuring hygienic transfer of fluids without contamination.

The specific choice of rotary joint depends on the requirements of the application, such as the type of fluid or signal being transferred, rotational speed, environmental conditions, and industry standards.

Contact us Cell: +91-8433777035 or Email: info@sealomech.com