Mechanical seals and pumps O&M, troubleshooting in process plants

Mechanical seals and pumps O&M, troubleshooting in process plants

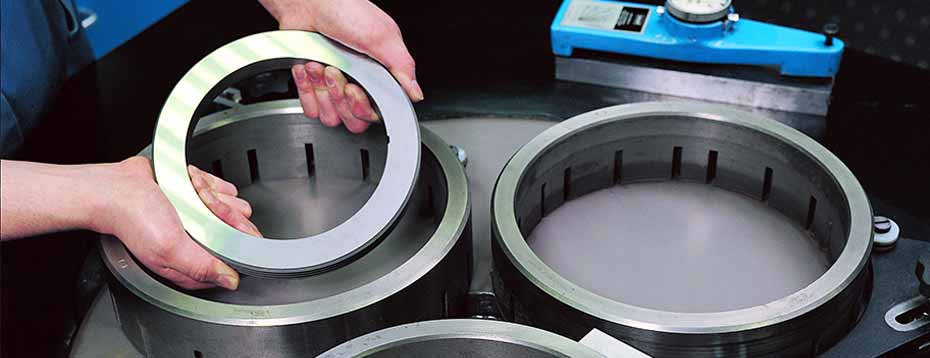

With our designs and range of Mechanical seals we can deliver leak free liquid transfer from pumps in different processes for your plants

Referring to "industrial sealing technology." If that's the case, industrial sealing technology involves the development and application of various methods and materials to create effective seals in industrial settings. Sealing technology plays a crucial role in preventing leaks, contamination, and other potential issues in machinery and equipment.

Here are some key aspects of industrial sealing technology:

- Materials: Various materials are used for seals, including rubber, elastomers, plastics, metals, and composite materials. The choice of material depends on factors such as the operating environment, temperature, pressure, and the type of fluids or gases being sealed.

- Types of Seals:

- Gaskets: Used to create a barrier between two surfaces, preventing leakage.

- O-rings: Circular seals often used in dynamic and static applications to prevent the passage of fluids or gases.

- Lip Seals: Commonly used in rotating shafts to prevent the escape of lubricants and to keep contaminants out.

- Mechanical Seals: Found in pumps and other rotating equipment to prevent the leakage of liquids.

- Applications:

- Automotive Industry: Sealing technology is critical in engines, transmissions, and various automotive components to prevent fluid leaks and ensure proper functioning.

- Oil and Gas Industry: Sealing technology is used in pipelines, valves, and other equipment to prevent leaks and ensure the safety and efficiency of operations.

- Aerospace Industry: Seals are essential in aircraft components to maintain pressure differentials and prevent the escape of fluids or gases.

- Manufacturing and Processing Plants: Seals are used in pumps, valves, and other equipment to maintain operational efficiency and prevent environmental contamination.

- Testing and Quality Control: Ensuring the reliability of seals is crucial. Various testing methods, such as pressure testing, leak testing, and material analysis, are employed to guarantee the performance of seals in different conditions.

- Innovation: Advancements in materials science and engineering contribute to the continuous improvement of sealing technology. Nanotechnology, for example, has opened up new possibilities for enhancing the properties of seal materials.

Effective industrial sealing is vital for the overall performance, safety, and reliability of industrial equipment. It helps prevent environmental damage, reduces maintenance costs, and ensures the efficient operation of machinery in various industries.

Contact us on: +91-8433777035 or Email: info@sealomech.com