Mechanical Seal Support System

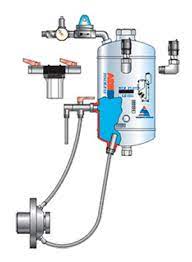

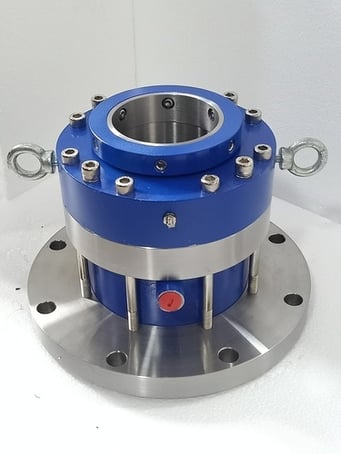

Sealomech provides a full range of Seal Support Systems for Pumps, Agitators and Mixers all ranging in sizes from seal pots, bearing guards etc.

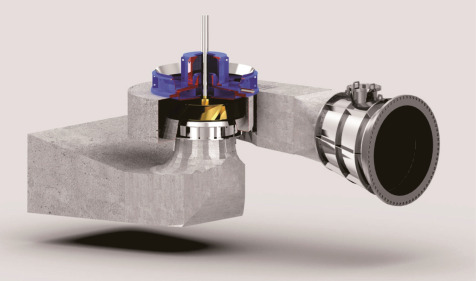

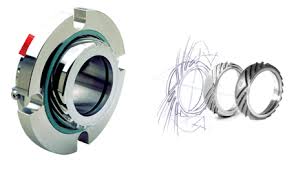

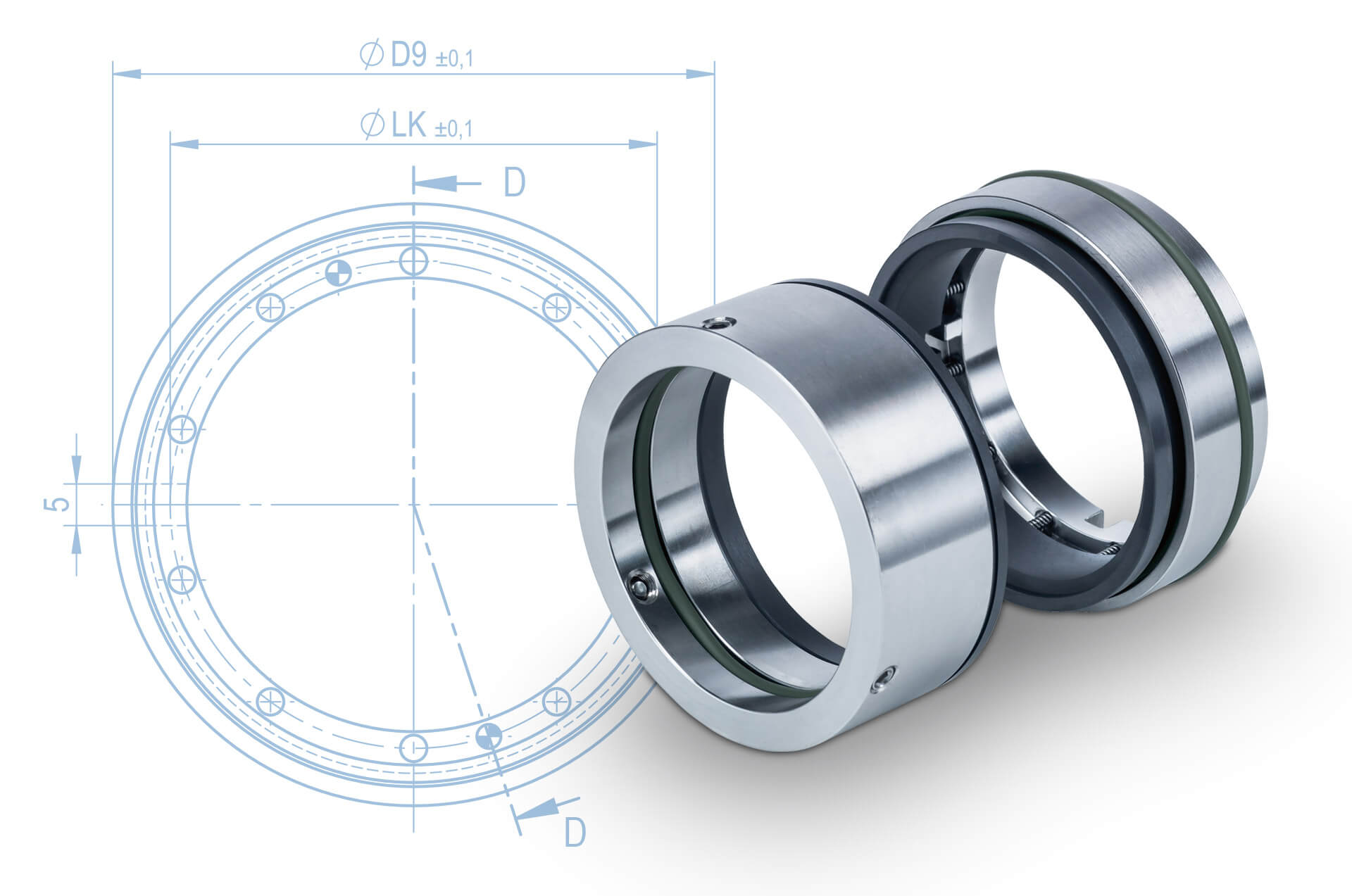

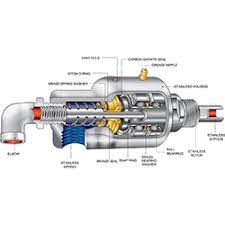

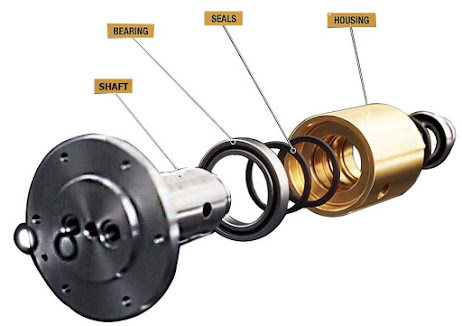

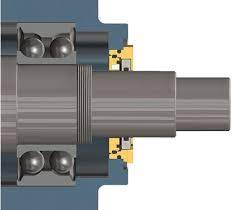

A mechanical seal support system is a crucial component in industrial applications where rotating equipment, such as pumps, compressors, and mixers, require a seal to prevent leakage of fluid from the process. Mechanical seals are used to create a barrier between the rotating shaft and the stationary part of the equipment, ensuring that the fluid remains contained within the system.

The support system for mechanical seals is designed to enhance the performance and reliability of the seals. Here are some key aspects of a mechanical seal support system:

- Flush Systems:

- Barrier Fluids: These systems involve introducing a clean and compatible fluid between the sealing faces. This fluid acts as a barrier, preventing the process fluid from leaking out and providing lubrication to the seal faces. The barrier fluid is usually at a higher pressure than the process fluid.

- Gas Seals: In certain applications, a gas, such as nitrogen, is used as a barrier to prevent leakage. Gas seals are common in high-pressure and high-speed applications.

- Quench Systems:

- Quenching: In some applications, especially those involving hazardous or volatile fluids, a quenching system is used to cool and flush the mechanical seal area. This helps in preventing the process fluid from reaching the seal faces.

- Cooling Systems:

- Cooling Jackets: Mechanical seals may generate heat due to friction during operation. Cooling systems, such as jackets with coolant circulation, help dissipate this heat, preventing the seal faces from overheating and ensuring longer seal life.

- Monitoring and Instrumentation:

- Temperature and Pressure Sensors: Monitoring devices are often integrated into the support system to track the temperature and pressure of the seal area. This information can be crucial for preventive maintenance and avoiding seal failure.

- Flushing Plans:

- Plan Selection: Depending on the application and the type of fluid being sealed, different flushing plans may be employed. Plans could include single or dual flushing, as well as plans involving external reservoirs.

- Seal Support Reservoirs:

- Reservoirs: These are containers or systems that hold the barrier fluid or quenching fluid. The design and capacity of the reservoir are important factors in maintaining the effectiveness of the mechanical seal support system.

- Filtration Systems:

- Filtration: To ensure the cleanliness of the barrier fluid, filtration systems may be incorporated to remove particles and contaminants that could otherwise damage the seal faces.

- Emergency Support Systems:

- Backup Systems: Some applications may require emergency support systems, such as backup fluid supplies, to prevent catastrophic failure in case of a primary system malfunction.

Proper design, installation, and maintenance of a mechanical seal support system are essential for ensuring the reliable and efficient operation of rotating equipment in industrial processes. Regular monitoring and adherence to recommended maintenance practices contribute to the longevity of mechanical seals and the overall performance of the system.

The biggest mechanical preventative of mechanical seal failure is the use of effective Seal Support Systems, It proves that how well designed your mechanical seal or bearing systems are, without a reliable Seal Support System there is still the possibility of your mechanical seal failing. To overcome such issues Sealomech Engineering provides their valuable customers the confidence to remove this root cause of mechanical seal failure.

Cobus Bester March 20, 2020

Really happy with this print. The colors are great, and the paper quality is very good.

Cobus Bester March 12, 2020

Really happy with this print. The colors are great, and the paper quality is very good.

Cobus Bester March 11, 2020

Really happy with this print. The colors are great, and the paper quality is very good.