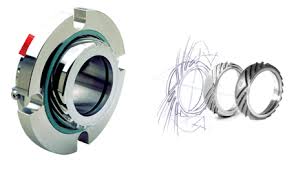

DIN 24960 is a standard proposal for mechanical seals

Sealomech follows DIN 24960 is a standard proposal for mechanical seals which includes technical specifications, stuffing box dimensions, and codes of materials.

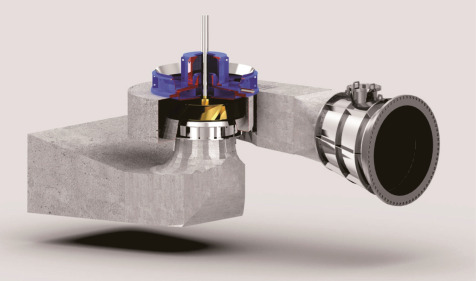

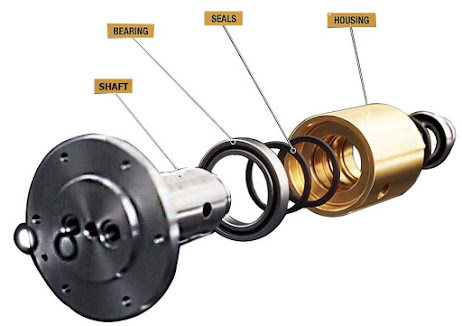

DIN 24960 is a German standard for mechanical seals used in pumps and similar equipment. Mechanical seals are used to prevent leakage between two rotating or reciprocating parts in machinery such as pumps, compressors, and mixers.

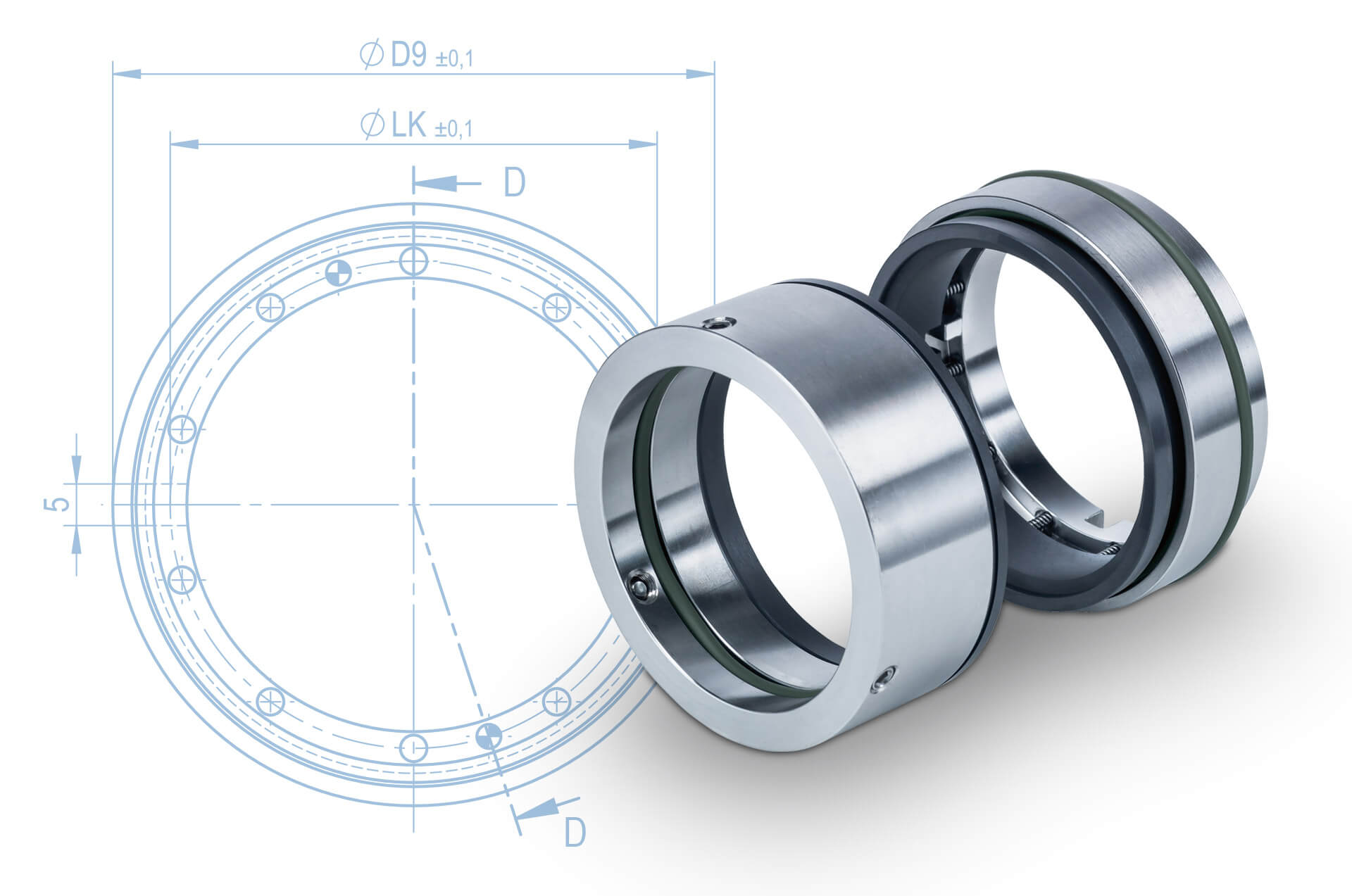

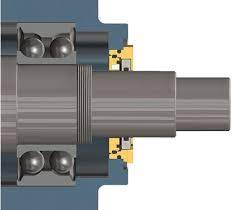

The DIN 24960 standard specifies requirements for the dimensions, materials, testing, and performance of mechanical seals. It aims to ensure interchangeability and compatibility between seals from different manufacturers, facilitating ease of replacement and maintenance.

Key aspects covered by the DIN 24960 standards may include:

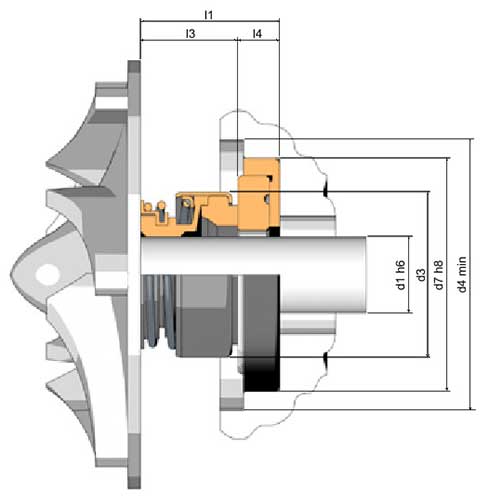

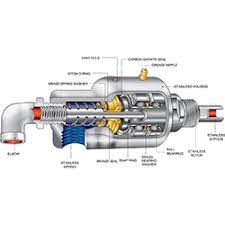

- Dimensions: The standard defines the dimensions of various components of the mechanical seal, such as the seal face, seal gland, and elastomeric parts. These dimensions ensure proper fit and function within the equipment.

- Materials: DIN 24960 specifies the materials that can be used for different components of the mechanical seal, considering factors such as chemical compatibility, wear resistance, and temperature tolerance.

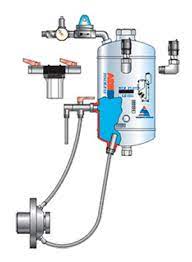

- Testing: The standard may outline testing procedures and criteria to ensure that the mechanical seal meets specified performance requirements, such as leakage rates, pressure resistance, and durability.

- Performance: DIN 24960 may specify performance criteria for mechanical seals, including parameters such as operating temperature range, pressure rating, and expected service life.

Overall, DIN 24960 provides guidelines for the design, manufacture, and testing of mechanical seals to ensure reliable and efficient operation in various industrial applications. Adherence to this standard can help manufacturers produce high-quality seals that meet the requirements of their customers.

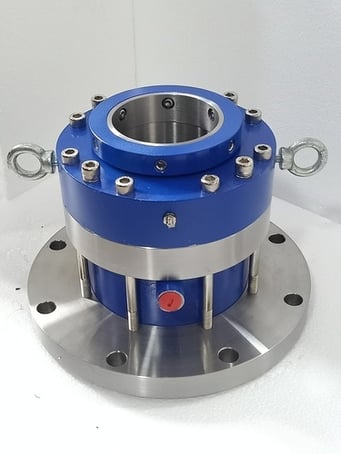

Sealomech Engineering has designed this in compliance with DIN 24960 standards and can be used in a wide range of applications, in particular in cases in which the fluids have a tendency to solidify. The seal has been subject to continuous development over time, enhancing its robustness and reliability. We at Sealomech Engineering believe in quality and class in engineering excellence rather than volumes. This is reflected in our predominant position in the higher end seals market in India.

Cobus Bester March 20, 2020

Really happy with this print. The colors are great, and the paper quality is very good.

Cobus Bester March 12, 2020

Really happy with this print. The colors are great, and the paper quality is very good.

Cobus Bester March 11, 2020

Really happy with this print. The colors are great, and the paper quality is very good.